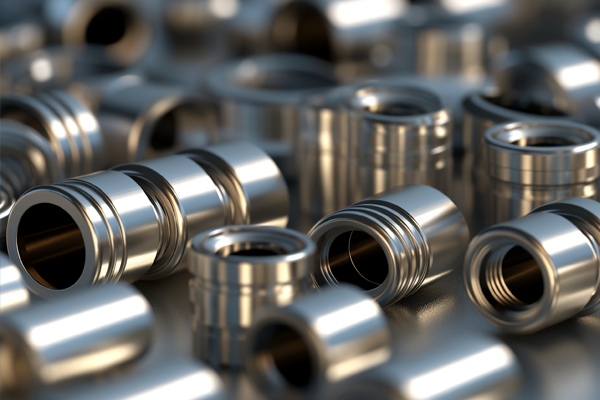

The machining method commonly seen in the machining process of precision machine parts is turning machining and milling parts, and some general precision parts are milling parts or turning parts. After the rough milling of the workpiece, the whole workpiece is actually very close to the appearance and size required by the workpiece itself. Dimensions will also be more accurate.

A precision machined part usually goes through one rough shave and one finish shave to achieve the required appearance and dimensions of the part. However, not all workpieces are cut once, and some workpieces may require more than one rough cutting. In addition, the accuracy requirements of the workpiece itself may not be very high or the cutting amount may be small, and in some cases, the requirements of the workpiece can be met with a single finish cutting.

In the machining of precision machine parts, crude cutting requires a large amount of cutting residue for the workpiece, so it needs to have a larger cutting force than precise cutting, which requires that the machine, tool and workpiece can be matched, and crude cutting is unexpected It is possible to remove the remaining amount quickly, and the surface performance after the effect should not be too rough.

Precision machinein precision cutting of machining parts, the surface performance and dimensional accuracy of the workpiece reach the requirements of the workpiece, so the tools required for precision cutting also need to be very sharp, and because the cutting amount is small, there are very high requirements for measurement accuracy.

In fact, many of the parts we do not see have an inseparable relationship with precision machine parts processing. For example, very fine nuts in mobile phones, because these nuts are actually customized to the needs of mobile phone manufacturers, and there are few standards, and the requirements for precision are very high, almost all precision machines. Production is dependent on machining.